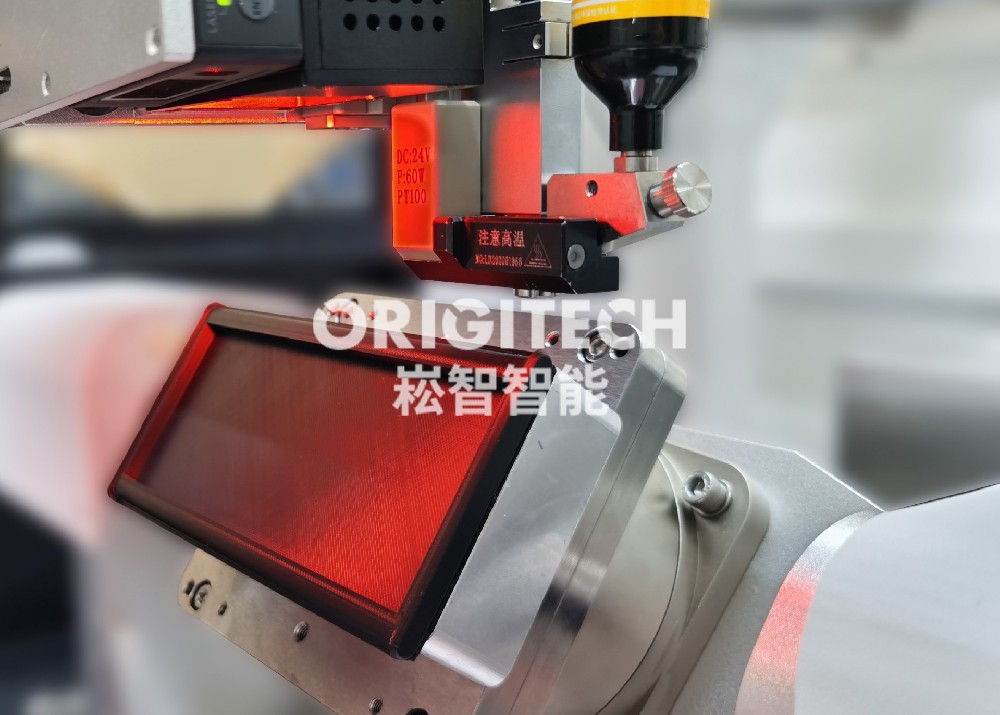

3D 5-axis precision laser cutting

From:ORIGITECH

Time:2021-11-11

This project is the application of ORIGITECH's complex trajectory control system in the field of laser cutting, which helps customers to launch and expand their laser cutting production line in the field of 5-axis synchronization. The combination of complex trajectory control system, automatic calibration system AOS-Control-Calibration and laser cutting technology provides customer a complete technical solution of 5-axis precision laser cutting.

Features of the solution

The rapid import of workpiece model into digital twin software combined with AOS automatic calibration system helps customer with flexible processing recipes exchange

The open interface of digital twin software for point positioning and posture provides laser engineer possibility for fine adjustment of path planning

With RTCP technology to ensure the precise focal control and the best posture relationship between laser and workpiece during the processing

This technical solution is also suitable for laser cutting with industrial robot